When an optimization needs to schedule the execution of pickup or delivery orders, the delivery (resp. pickup) task needs to be executed at a depot. Therefore, at least one depot needs to be specified when the optimization request contains pickup or delivery orders.

When scheduling a depot task, the optimization process selects the most suitable depot that fits both the order and the vehicle. Selecting a depot for a depot task applies certain properties automatically to the depot task (see below), while others are defined by the depot task properties at the order level.

Location

Each depot has a designated location. The optimization will select the most suitable depot, and therefore the most optimal location to pickup or deliver an order.

Time slots

The location of a depot specifies time slots to execute pickups or deliveries at the location. A depot may impose additional limitations on the selection of these available time slots for tasks scheduled at this depot.

Categories

Certain constraints are not only specific to the depot but entail different entities such as vehicles or orders. These constraints are typically expressed based on categories, which are often functional properties of the depot itself. Examples of categories might be whether a depot contains cooled goods, the geographical region a depot is located in or any other essential property associated with the depot.

Maximum loads constraints

A depot can define limits on the loads that may be executed there. These constraints specify how much can be delivered to (inbound) or picked up from (outbound) the depot. When planning tasks, the optimization makes sure that the required loads do not exceed these limits.

Inbound example: Waste Transfer Station daily intake limit

A waste transfer station (the depot) can only accept 40,000 kg per day due to permit limitations. You have several collection routes dropping off municipal waste at that station. By specifying maximum inbound loads, optimization will ensure that the total delivered to that depot does not exceed 40,000 kg.

{ "maximumLoads": { "inbound": [ { "dimension": "Kilogram", "value": 40000 } ] } }

Outbound example: Banana stock cap at start of optimization

A fresh-produce depot starts the day with 1,000 bananas in stock. By specifying maximum outbound loads, optimization will ensure total bananas picked from this depot is at most 1,000 across all assigned tasks.

{ "maximumLoads": { "outbound": [ { "dimension": "Bananas", "value": 1000 } ] } }

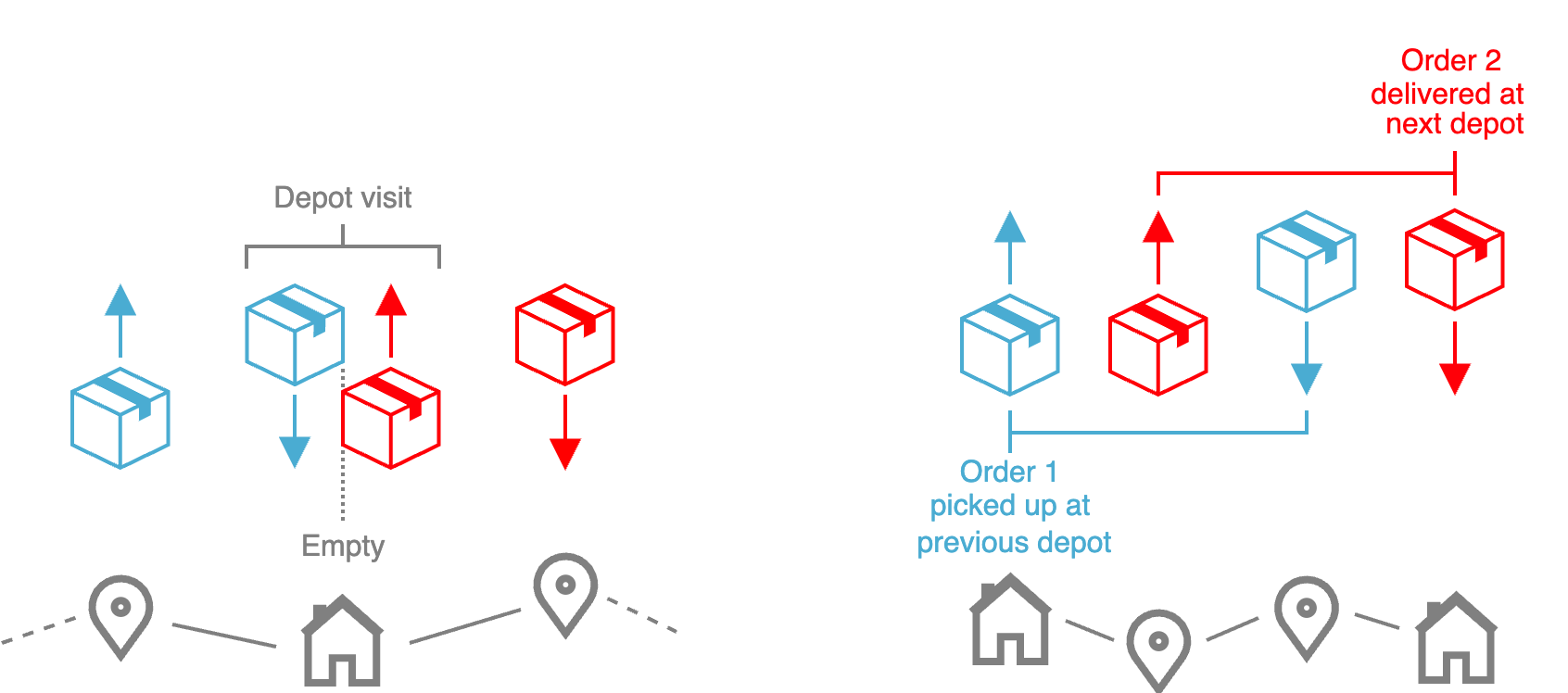

Depot visits

Orders are delivered at the depot in the opposite order they were picked up. Similarly, orders are picked up at the depot in the opposite order their delivery will be scheduled.